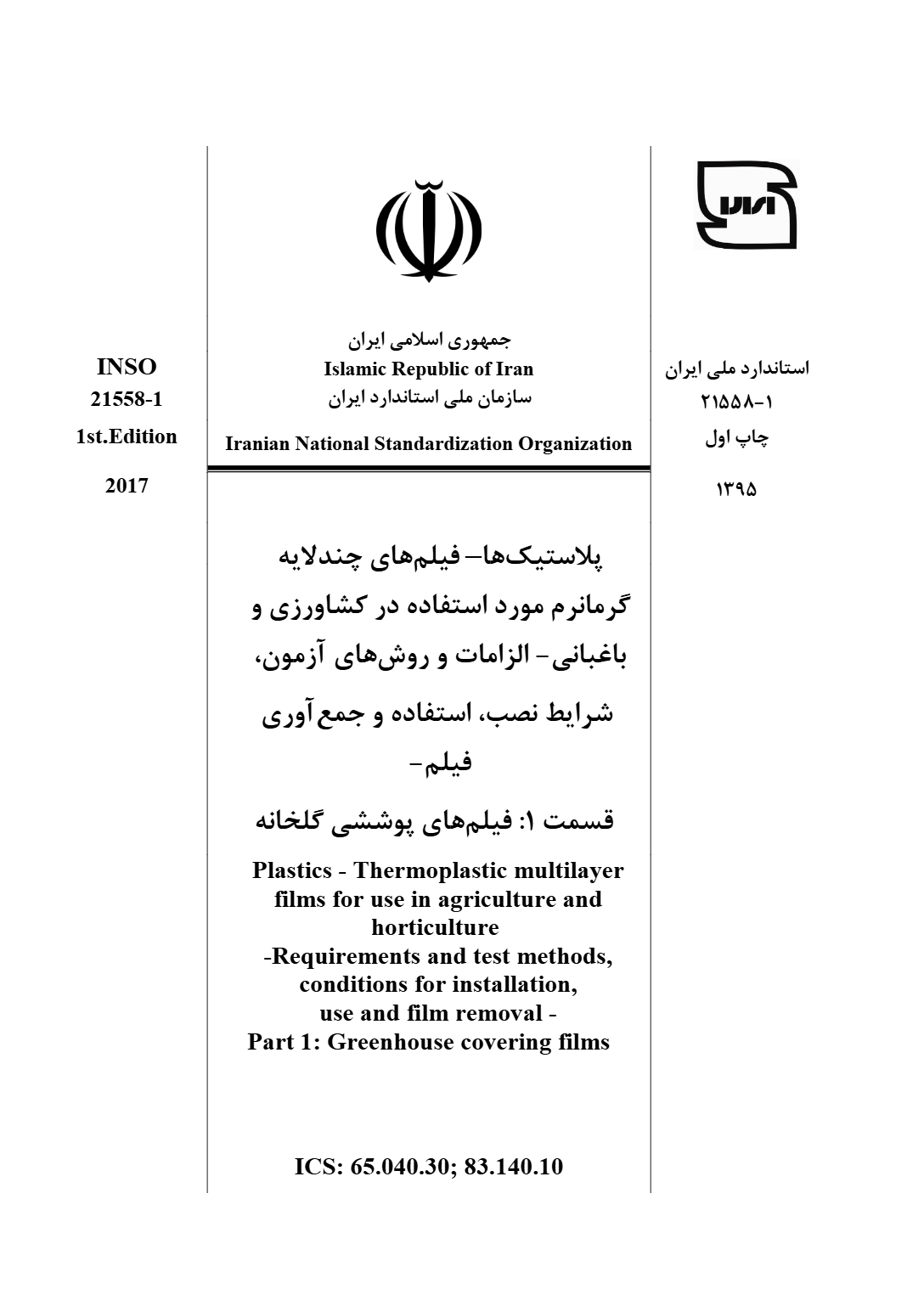

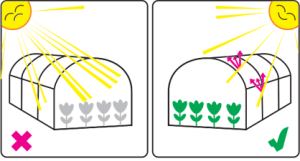

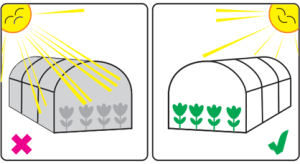

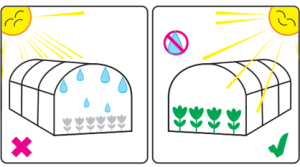

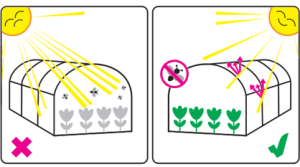

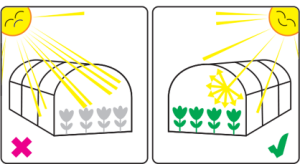

Light Diffuser: The light that passes through the film and enters the greenhouse is divided into direct and diffused light. Although films with this additive may appear cloudy to the naked eye, this does not mean reduced light transmission. Light diffusion reduces plant shadowing and ensures even light distribution throughout the greenhouse, allowing all parts of the plant—especially the lower sections—to receive adequate light. It also helps prevent sunburn and provides a moderate cooling effect.